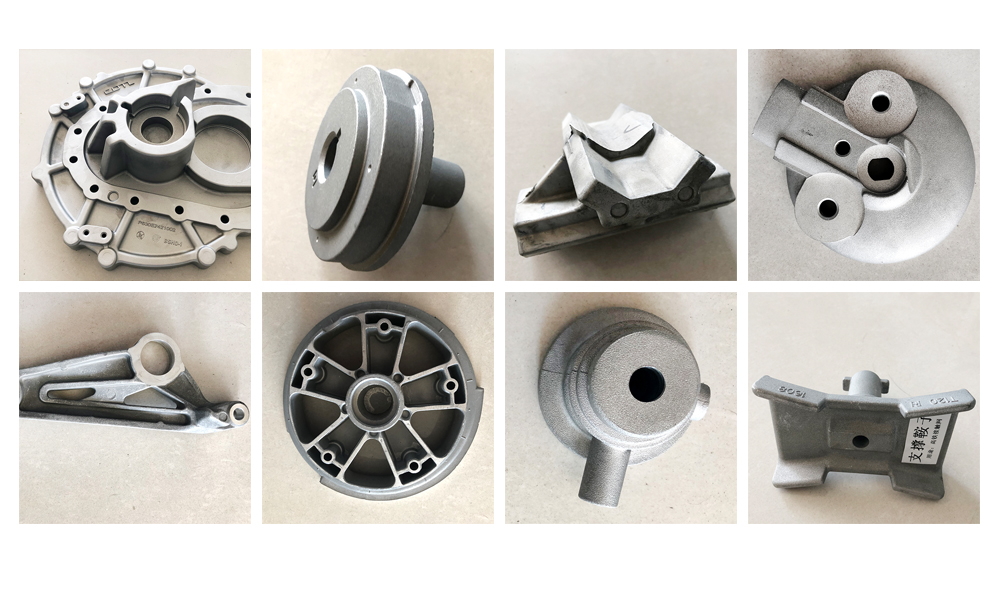

3D liquid forging parts

3D liquid forging parts

Fully smart 3D liquid forging machine

Free your hands

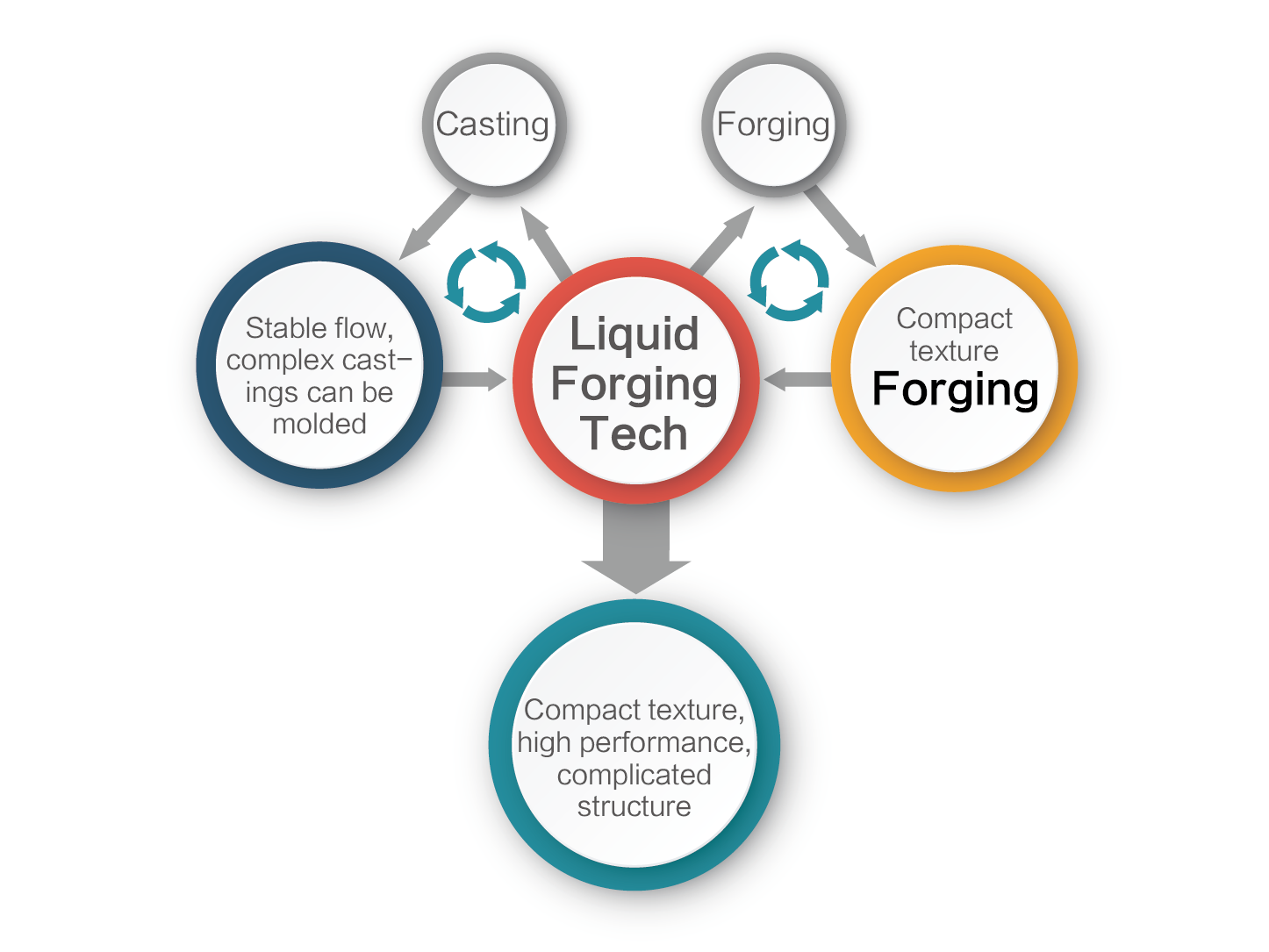

3D liquid forging principle and processing

Liquid forging (LF) is an innovative manufacturing process combining casting and forging techniques.

In the LF process, a pre-quantified amount of molten metal is poured into a die cavity and squeezed under pressure during solidification to form components in a single process utilizing re-useable dies.

Our LFT molding produces the most compact texture cavity free, leading to better physical performance.

Properties and Highlights

The keys advantages of our LF lie in its ability to produce near net shape components that are:

1. Tighter inner structure

2. Smoother surface to facilitate further processing

3. Parts made from LFT tech more precise in size

4. Light Weight

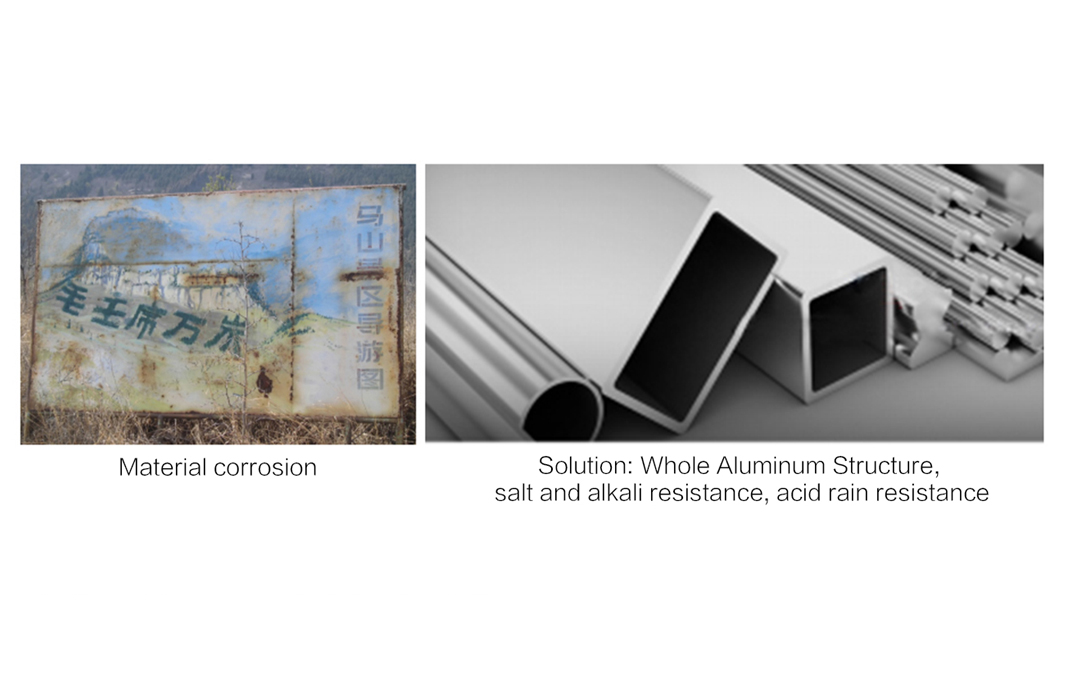

5. Corrosion Free

6. Better physical performance

7. Porosity free

8. High-aspect ratio features

9. Reduce materials wastage by the elimination of runners and gating

Core competitiveness

Our 3D liquid forging tech matches the military standards, we produce parts of complex shapes with low cost, improved physical performance and significantly reduced weight lead to better energy efficiency and durability. We are able to make products structure design and CAE analysis, and we can customize and develop alloy products according to customers’ requirements.